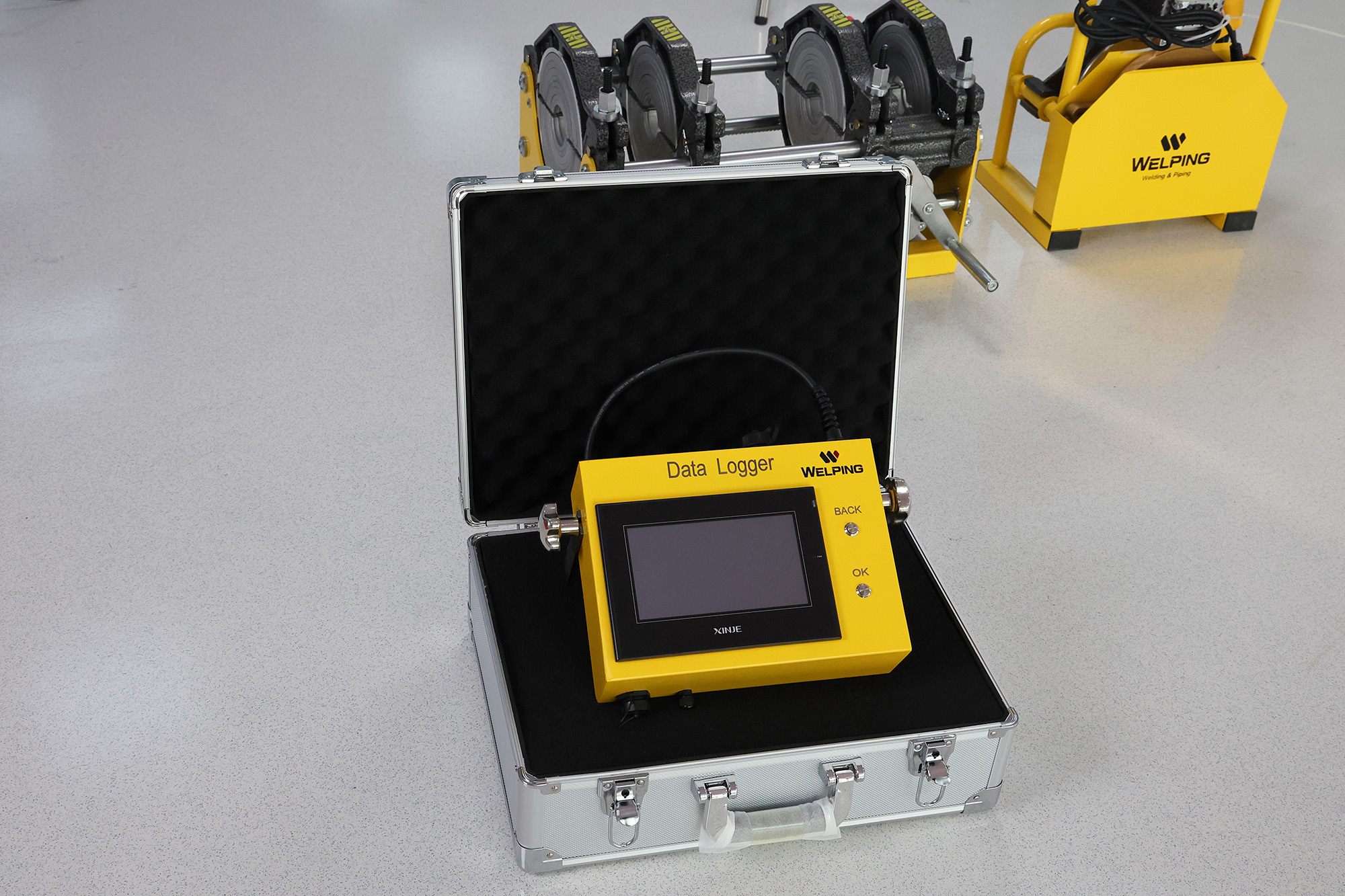

To further enhance control and traceability in your production process, we proudly introduce the advanced data logger equipped with our plastic pipe butt welding machines. This device is not just a technological advancement; it is a reliable assistant for your factory’s quality management.

Our data logger can capture and record critical production data in real-time, including temperature, pressure, and time. With high-precision sensors and advanced data processing technology, it ensures that every step of the process is accurately captured and stored. This not only helps in monitoring the production status in real-time but also enables factory managers to quickly identify potential issues and make immediate adjustments, thereby ensuring production efficiency and product quality.

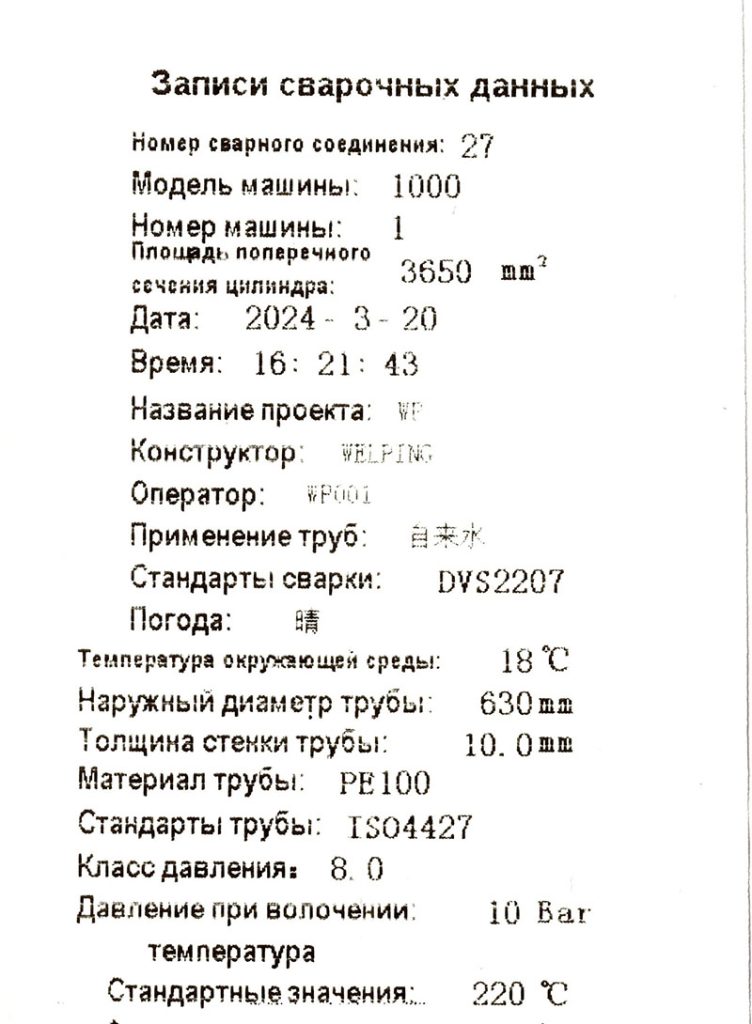

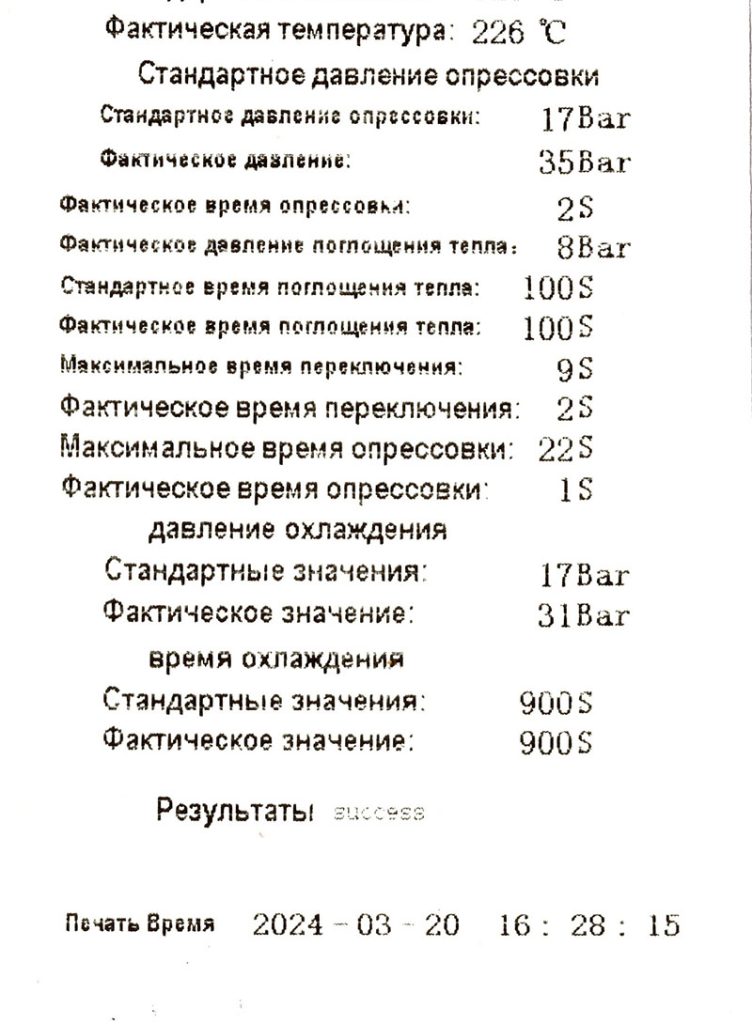

This is our data report. The language can be customized. There are multiple languages such as English, Russian, Spanish, etc.

Additionally, our data logger supports data export and analysis functions, allowing for the generation of detailed production reports and trend analyses. This provides the management with a scientific basis for optimizing production planning and resource allocation. Whether it’s for quality traceability or continuous improvement of production efficiency, this tool will become an indispensable part of your operation.

Choosing a plastic pipe butt welding machine equipped with a data logger means opting for more efficient and precise production management methods. Please contact us to learn more about how this innovative technology can add value to your production line.