#hydraulic butt fusion welding machine

#butt welding machine

#butt fusion machine

#https://welpingfusion.com/

#https://welpree.com/

# https://www.facebook.com/102390185489308

Similar Posts

butt welding machine-63-200mm#hdpe pipe jointing machine#manufacturer#butt joint machine

Our machines are ideal for welding pipes made from a range of materials, including HDPE, PP and PVDF. in addition, our machines are suitable for a range of applications, including water supply, gas distribution and chemical transport systems.

How to test the welding quality of butt welding machine

https://welpingtek.com/

butt welding machine

butt fusion machine

fusion welding machine

butt fusion welder

thermofusion machine

jointing machine

thermofusion welding

Electric Hydraulic Welding Machine China Manufacturer For Factory Price

https://welpingtek.com/

Butt fusion welding is an effective, trouble-free connecting method for PE, HDPE, PP pipes. In pressurized piping applications, butt fusion welding can provide excellent performance, just like a whole pipe. WP160A provides standard welding range of 63mm to 160mm, size 40 and 50mm are optional.

#hydraulic #fusion #hdpe #butt welding machine

electric hydraulic welding machine 180-450mm#High Quality#gas pipeline#China manufacturer

Our machines are ideal for welding pipes made from a range of materials, including HDPE, PP and PVDF. in addition, our machines are suitable for a range of applications, including water supply, gas distribution and chemical transport systems.

Hangzhou Welping Machinery Equipment Co.,Ltd

Factory: Puyang town Xiaoshan District, Hangzhou, China

Office: Room 1906 Building 1, Taifu Plaza, No. 1 Tonghui Middle Road, Xiaoshan District, Hangzhou

Tel: 00 86 571 82603031

Mobile: +8617774005155 (WhatsApp)

FB: ella@welping.cn

Web: www.welpingfusion.com

hdpe pipe jointing machine price#manufacturer #gas #pipe

This machine is 450mm and can process tubes from 180-450mm

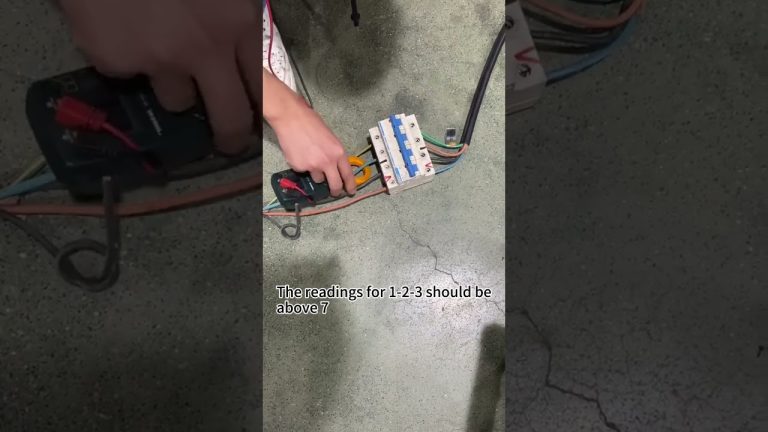

How to test the circuit connection of the butt welding machine?

How to test the circuit connection of the butt welding machine? The video demonstrates the use of a clamp ammeter for this purpose.